Get a Quote

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.

This project adopts multimedia filtration and reverse osmosis to recycle the wastewater discharge from the power plant so that the product

water can be reused in other processes in the plant.

Pretreatment + Ultrafiltration + Reverse osmosis

Past project capacity: 2400m3/d ‒ 17760m3/d

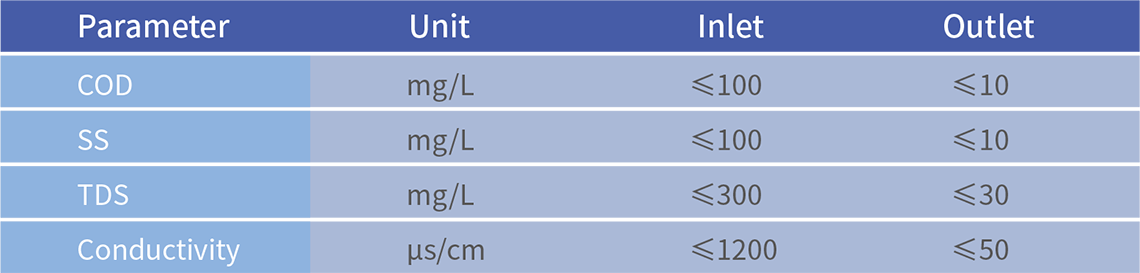

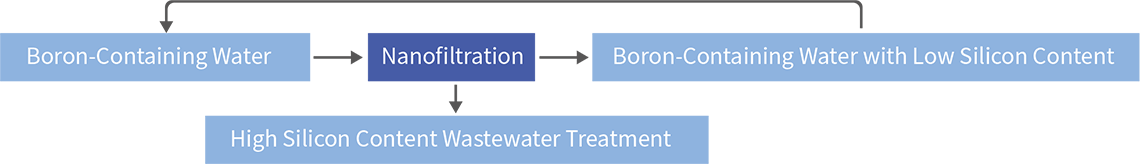

Nuclear power plants require a limited value of dissolved silicon content in boron-containing

water system of primary circuit. When the silicon content of the primary boron containing water system exceeds the safety limit, the boron-containing water system needs to be purified and the silicon concentration should be reduced to the safety limit, so as to ensure the safe operation of units. The chemical and physical properties of dissolved silicon are very close to those of boric acid, making it very difficult to separate dissolved silicon from boric acid. Due to strict water quality requirements in nuclear power plant, impurities cannot be introduced while removing dissolved silicon. At the same time, it is necessary to ensure a high recovery rate of boric acid

and control the generation of waste from nuclear power plants.

The application of nanofiltration membrane technology can reduce the silicon concentration in the boron containing water system to a safe limit (<500ppb), while minimizing the discharge of waste liquid as much as possible to ensure stable boron concentration in the system.

Compact design with small footprint

CIP free and without impurities introduced

Fully automatic control, easy to operate, complete safety precautions

You can ask any questions you may have about our products, our company or our sales processes.

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.