Get a Quote

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.

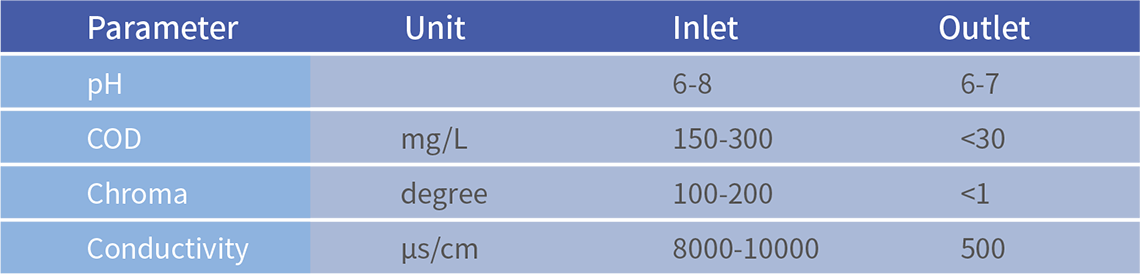

Leather industry adopts the double membrane process to recycle wastewater with high salinity and complex water quality. The product water can be used for other processes in leather production. This project significantly reduces the wastewater discharge and freshwater

consumption.

Pretreatment + Ultrafiltration + Reverse osmosis

Past project capacity: 2000m3/d ‒ 2700m3/d

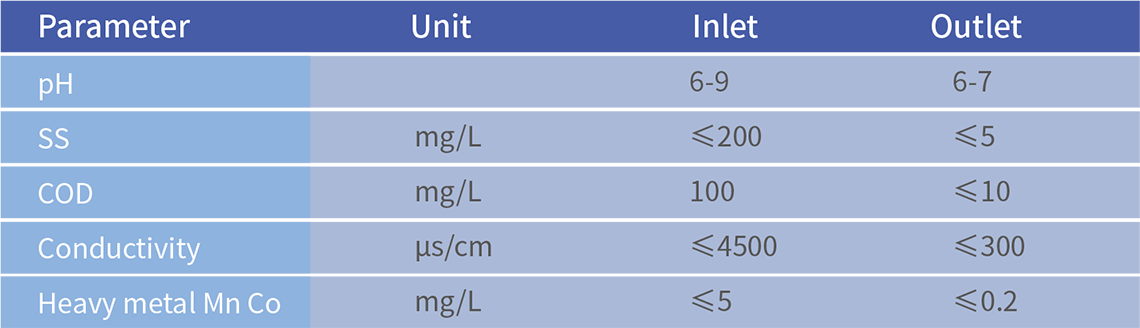

In the petrochemical industry, double membrane processes are used to recycle petrochemical wastewater with complex water quality. The permeate can be reused for circulating cooling water and pure water production. This process solves the problem of unstable operation that similar projects are facing and reduces water cost which has significant social and economic benefits.

Pretreatment+Ultrafiltration+Reverse osmosis

Past project capacity: 1680m3/d ‒ 31200m3/d

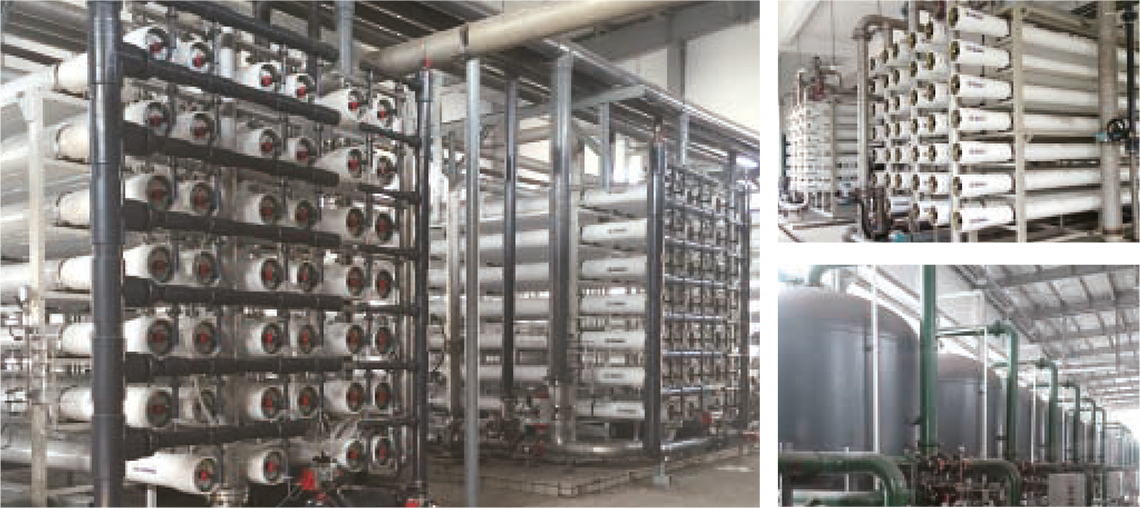

PTA wastewater in the petrochemical industry has high acetic acid content. If the acetic acid in the water is recycled and returned to the main process, the consumption of fresh acetic acid will be reduced which brings considerable economic benefits to the company.

The industrial acetic acid recovery unit adopts the treatment process of heat exchanger cooling, pretreatment and two stage reverse osmosis. The concentrate is returned to the main process and the permeate is transported to the wastewater treatment system.

The water to be treated mainly contains acetic acid, p-toluic acid, terephthalic acis, methyl acetate, methanol, formaldehyde, etc. with high temperature and low pH. PTA wastewater is processed through cooling and membrane filtration to achieve product water recovery rate over 90%; acetic acid recovery rate over 80%; acetic acid content in the productwater as low as possible.

Pretreatment + Ultrafiltration + Reverse osmosis

Past project capacity: 720m3/d ‒ 6240m3/d

Wastewater Treatment

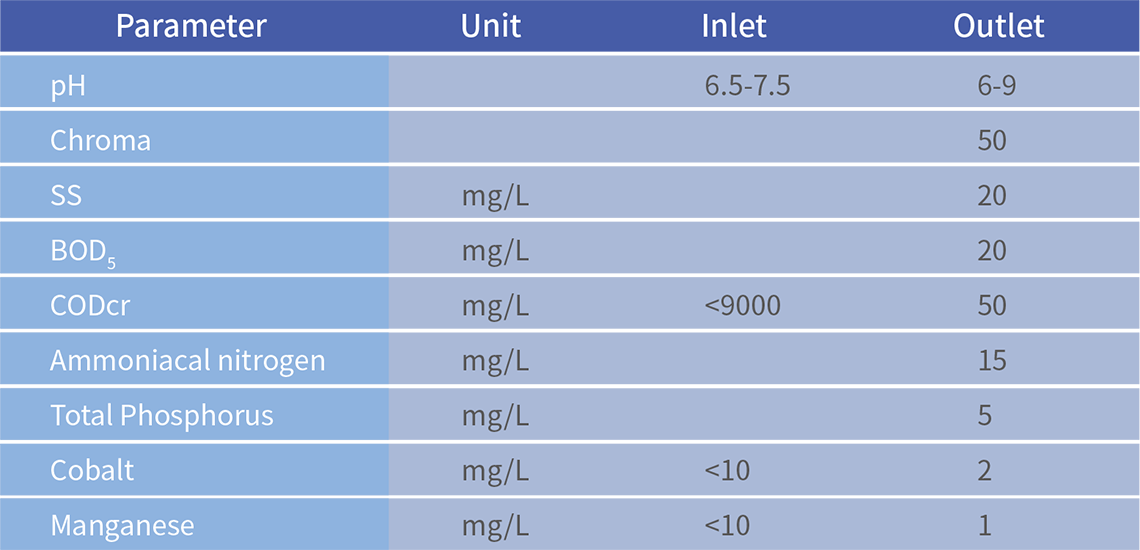

In 2016, Suntar carried out the expansion of the Jiaxing petrochemical Phase II project. In the petrochemical industry, PTA wastewater is difficult to treat due to the high COD and poor biodegradability. With extensive project experience, Suntar adopts the treatment processes of pretreatment, anaerobic and 2 stage aerobic treatment for the PTA wastewater. The treated water is then passed through double membrane treatment of ultrafiltration and reverse osmosis to meet the standards of circulation cooling water and pure water recycle.

Pretreatment+Ultrafiltration+Reverse osmosis

Past project capacity: 9600m3/d ‒ 71800m3/d

You can ask any questions you may have about our products, our company or our sales processes.

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.