Get a Quote

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.

As an important technology of dye post-processing, membrane separation has the characteristics and advantages of improving product quality, increasing product yield, expanding production capacity, saving raw and auxiliary material consumption while reducing environmental pollution, and meeting the requirements and specifications of cleaner production processes, and has been widely used in the dye industry.

Dye Recycling

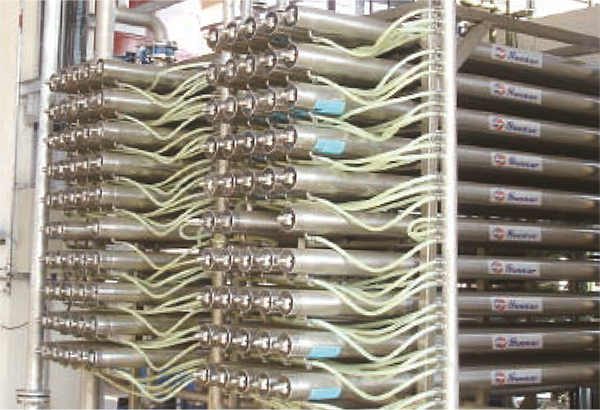

The dye is produced by the salt precipitation method, and the plate and frame filtrate contains a small amount of solid dye, which can be concentrated and recovered by membrane technology.

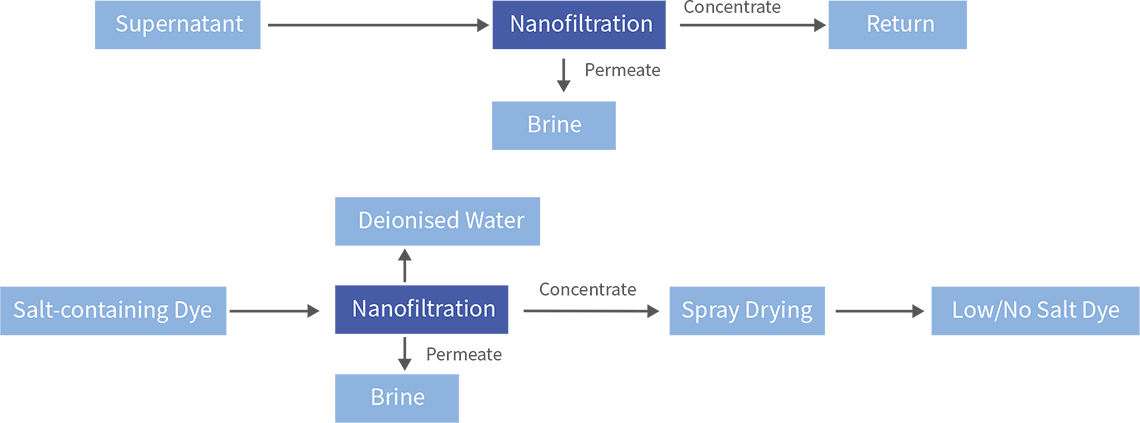

Dye Desalting and Concentration

Desalting and concentrating high-salt dyes by membrane technology can produce high-quality low-salt dyes and improve dye strength. Dye desalting can be used for various dye brighteners: disperse dyes, acid dyes, direct dyes, optical brighteners, etc..

Dye Wastewater Treatment

Zero-liquid Discharge of High Salinity Water

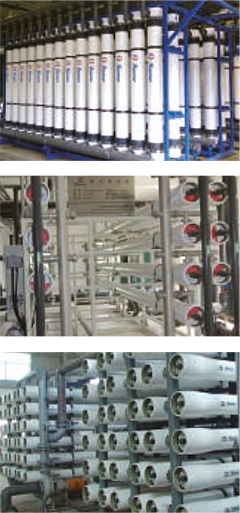

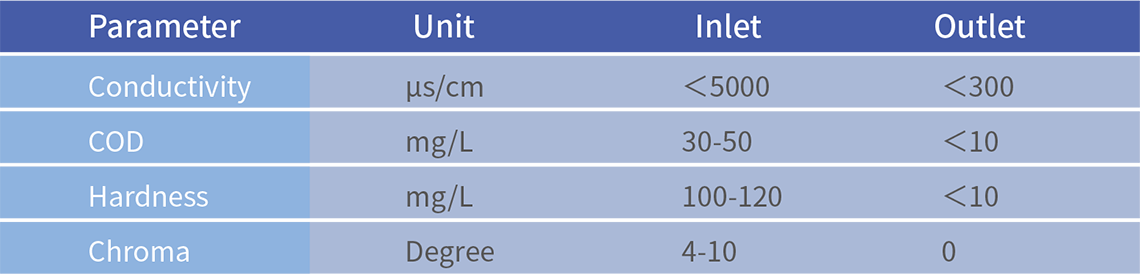

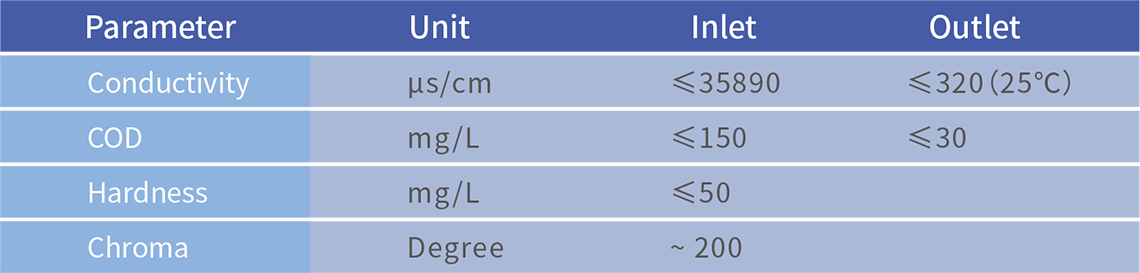

Recycle of textile discharge water with high salination, hardness, alkalinity, and chroma using double membrane technology. Product

water can be reused for production. Treatment capacity: 5000m3/d.

Pretreatment + Ultrafiltration + Reverse osmosis

Past project capacity: 1200m3/d ‒ 5000m3/d

To increase the overall recovery rate, the backwash water from multi-media filter and UF system is collected and recycled as feed water.

This increases the overall recovery rate of the system from 88.2% to 98.5% and reduces the amount of external drainage.

Pretreatment + Ultrafiltration + Reverse osmosis

Past project capacity: 4800m3/d

You can ask any questions you may have about our products, our company or our sales processes.

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.