Get a Quote

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.

In recent years, membrane separation technology in plant extraction has become more abundant. Suntar has also developed many applications in the plant extraction industry and an overall production process based on membrane separation technology and moving bed technology.

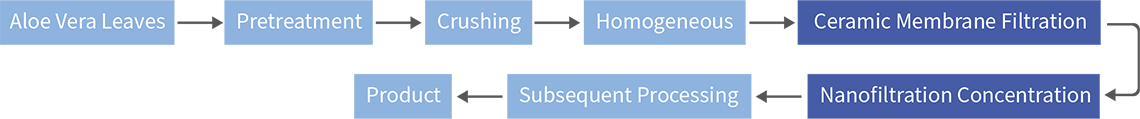

Ceramic membranes remove impurities and clarify extract which improves filtrate quality and recovery.

Nanofiltration concentration increases aloe vera juice soluble solid concentration from 0.75% over 7%

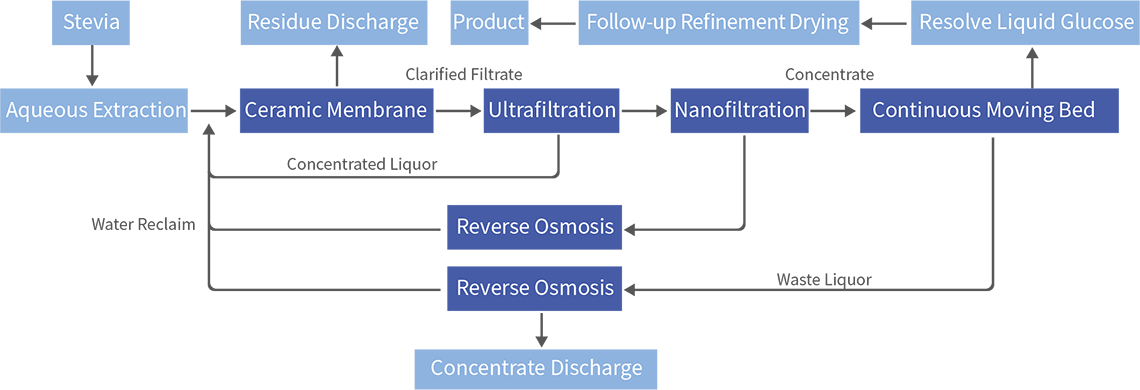

Membrane filtration has ideal impurity removal and clarification effect on stevia extract, and can better remove suspended solids, and pigments as well as improve product quality and yield.

Nanofiltration membrane increases the efficiency of resin adsorption and significantly reduces wastewater discharge. The filtrate can be discharged directly or be treated further and recycled.

Continuous moving bed reduces resin consumption by over 60% as well as reduces regenerant consumption and wastewater discharge by over 50%.

Wastewater treatment in each process becomes simpler with membrane. Membrane filtrate and the lower column waste of the resin adsorption process are fully recovered through reverse osmosis to achieve zero discharge.

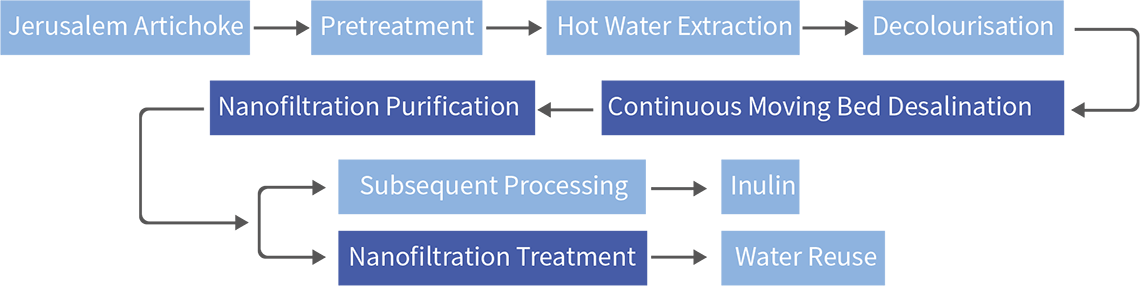

Continuous moving bed separates the extract, reduces the resin consumption by 60%, saves more than 50% of the regenerant, and reduces wastewater discharge by more than 60%.

Nanofiltration concentrates the product to meet the needs of the subsequent processes, improves recovery rate and reduces energy consumption.

Wastewater recovery through nanofiltration technology.

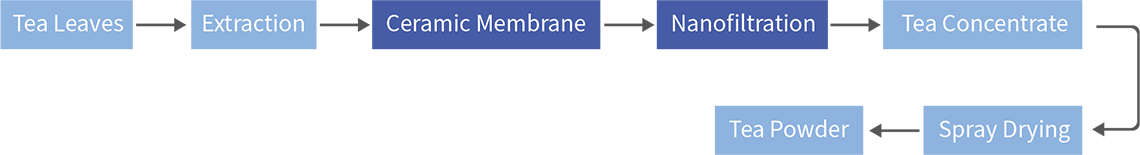

The principle of tea extract is very similar to that of Coca-Cola which involves the processing of standardised concentrated liquids or tea powder to produce finished beverages. Therefore, industrialised tea extraction is a revolution in the history of the tea industry.

From tea leaves to tea concentrates or tea powder, although the brewing process is easy, maintaining the original aroma and colour of the tea soup without precipitation is a technical difficulty in the food processing industry. The emergence of membrane separation technology is the most effective way to solve these problems.

Ceramic membranes remove impurity in the tea extract effectively to obtain clear tea extract.

Nanofiltration concentrates tea while retaining the flavour compound which can withstand high temperature filtration, cleaning and sterilization.

Sanitary design of membrane system to meet the requirements of healthy food production.

The development of salt lake lithium extraction technology began in the 1970s when a breakthrough in the technology of lithium extraction from the water was discovered and the lithium carbonate production cost was much lower than the extraction of lithium from ore. As such, salt lake lithium extraction has become a major trend and Suntar has developed different lithium extraction methods over many years to accommodate the characteristics of salt lake, to provide our customers with a complete salt lake lithium extraction membrane process.

Continuous Moving Bed Technology and Membrane Process Package (Magnesium-lithium separation, boron removal, concentration technology).

By means of moving bed adsorption, membrane, and resin coupling, a high-concentration, high-purity lithium-rich solution is extracted from the salt lake for the production of lithium salts.

You can ask any questions you may have about our products, our company or our sales processes.

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.