Get a Quote

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.

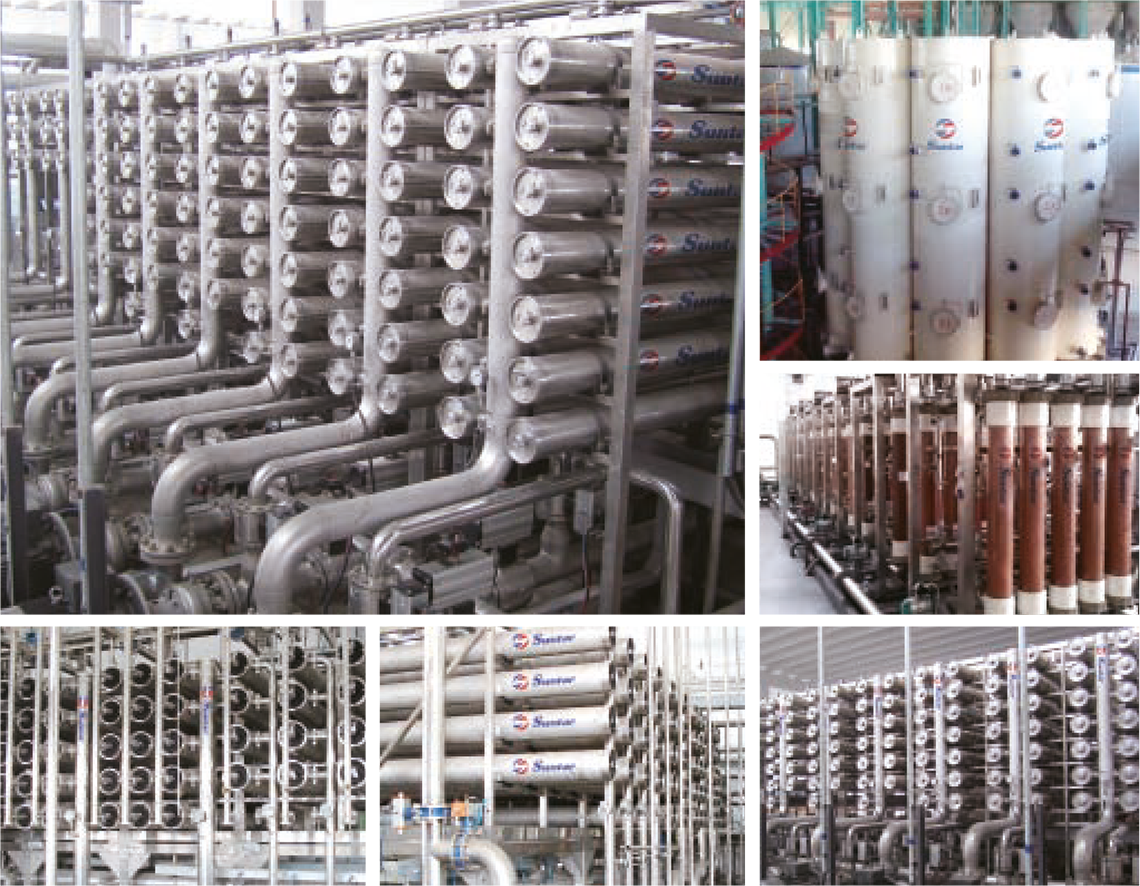

The increased demand for sugar pushes sugar manufacturers to innovate on the production process. Suntar developed a series of membrane separations with moving bed system for sugar production which are highly recognized by the sugar manufacturers.

Membrane and continuous moving bed system increase product quality with lower production cost. The system is fully automated with all day operation to ensure stable high production.

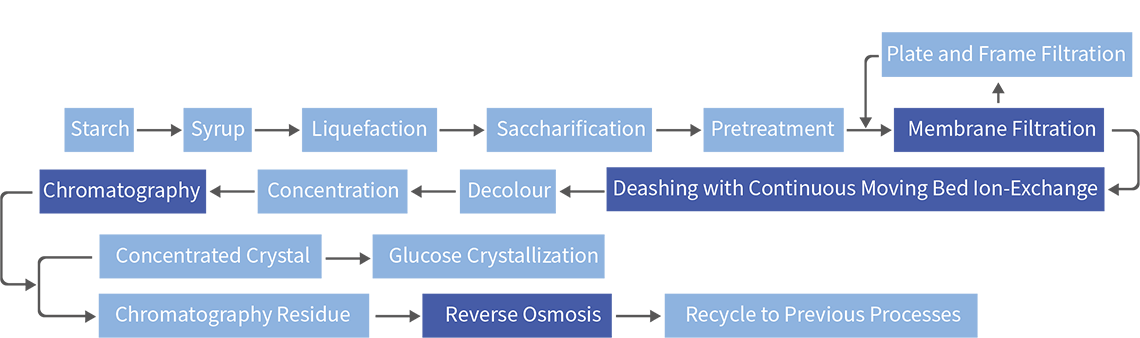

Membrane filtration to remove impurities in the saccharification liquid resulting in high quality filtrate which reduces subsequent resin pollution and the problem of saccharification liquid colour reversion.

Continuous ion-exchange moving bed deashing reduces resin consumption by over 70%, reduces regenerant and water consumption by over 50% and reduces over 60% wastewater discharge.

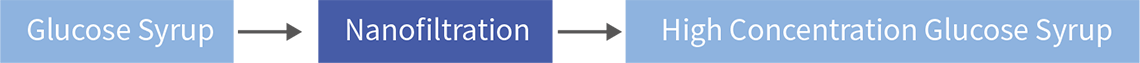

Nanofiltration purifies saccharification liquid resulting in high glucose purity in one step.

Suntar’s unique nanofiltration technology further perifies glucose / fructose from 96% to over 99.5%. Filtrate can be used directly for high purity glucose or fructose syrup production.

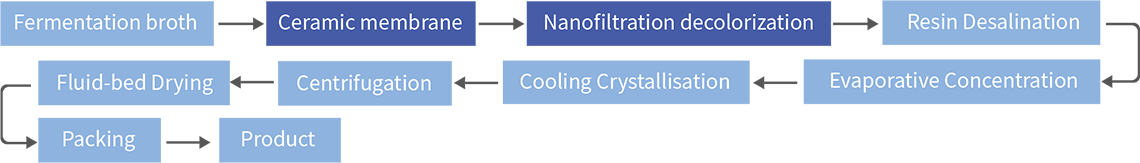

Suntar has applied membranes and continuous moving beds to the production of xylitol, erythritol, sorbitol, etc. and has developed a biological fermentation method for the extraction process of xylitol.

Ceramic membrane filters erythritol fermentation broth achieving high quality filtrate.

Nanofiltration removes impurities such as solube marcromolecular substances and pigments.

Simulated moving bed removes ash from erythritol, and reduces chemical and water consumption.

You can ask any questions you may have about our products, our company or our sales processes.

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.