Get a Quote

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.

Amino acid is a common name for a class of organic compounds containing amino groups and antelope groups, and there are more than 300 kinds of natural amino acids, of which about 22 kinds of amino acids are needed by the human body. Suntar's integrated separation solutions have been successfully applied in a variety of amino acid production processes, such as lysine, tryptophan, threonine, arginine, glutamine, leucine, valine, isoleucine, homoserine, methionine, citrulline, etc.

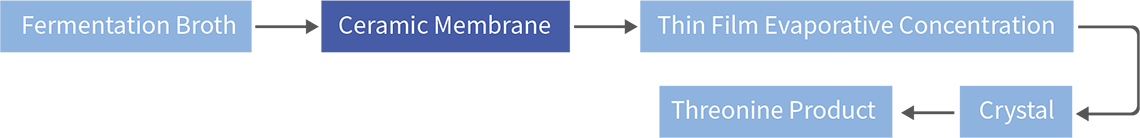

Threonine requires higher filtrate quality from ceramic membrane separation than other amino acids. Suntar developed threonine specific ceramic membrane with high precision and high resistance to abrasion.

Membrane filtration produces clear filtrate with 15% increased resin equivalent weight.

Less impurities in the pillar reduces the amount of water needed for resin regeneration which increase the resin lifespan and total yield.

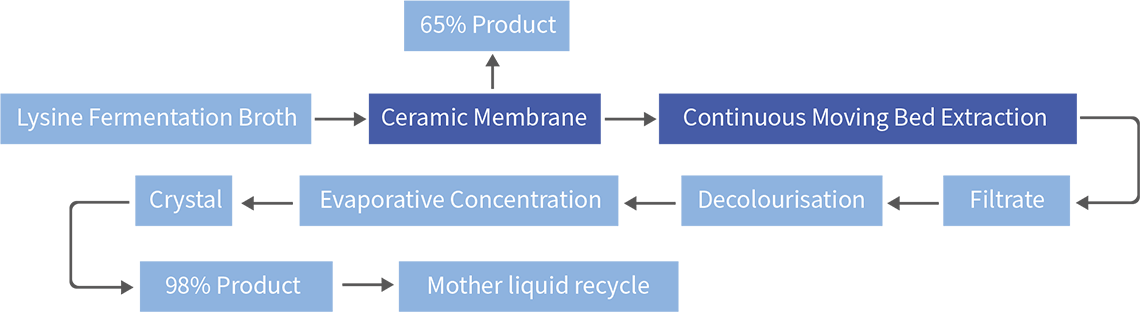

Membrane retains bacteria and protein in the fermentation broth which is then dried and processed into 65% lysine product.

Ion-exchange continuous moving bed dissociative adsorption increases resin utilization rate and the concentration of lysine in the permeate. this also reduces the consumption of water, analytical ammonia and wastewater discharge.

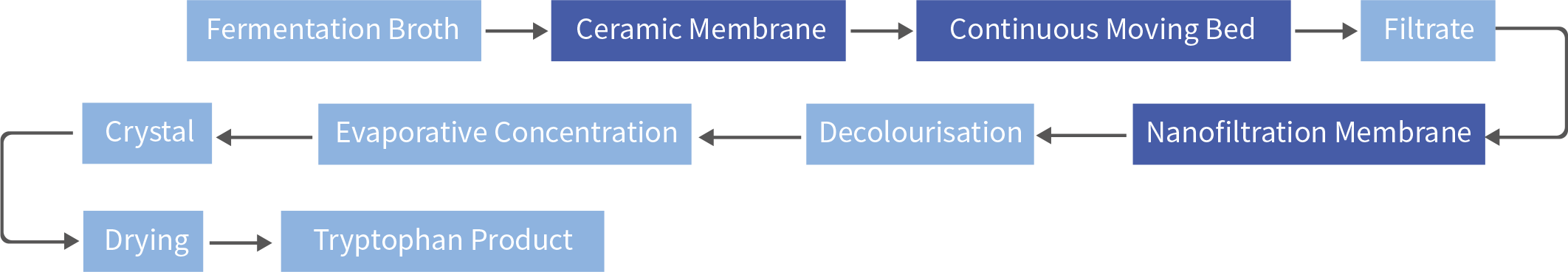

Ceramic membrane removes impurities and clarifies the permeate. This ensures high quality feed supplied to resin that ensures long lifespan of resin.

Continuous ion-exchange reduces chemicals and water consumption.

Nanofiltration removes impurities to improve the light permeability of tryptophan and lower the load of subsequent decoloring process.

You can ask any questions you may have about our products, our company or our sales processes.

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.