Get a Quote

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.

Membrane application in oil-water separation:

It is costly and difficult to treat wastewater from degreasing liquid directly. With ceramic membrane treatment, recycling of wastewater is achieved which reduces degreasing liquid consumption. This has a great potential in the market.

The oily wastewater passes through the adjustment tank and processed by ceramic membrane to meet the discharge standards, eliminating the need for coagulation, air flotation, sand filtration and other steps.

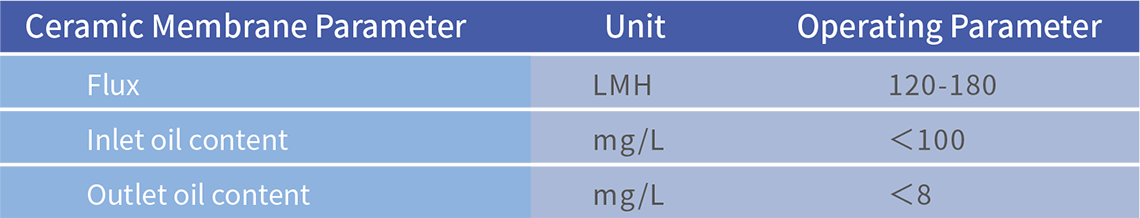

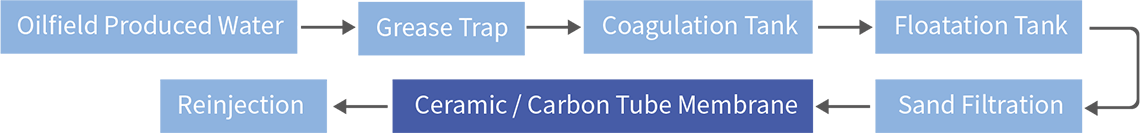

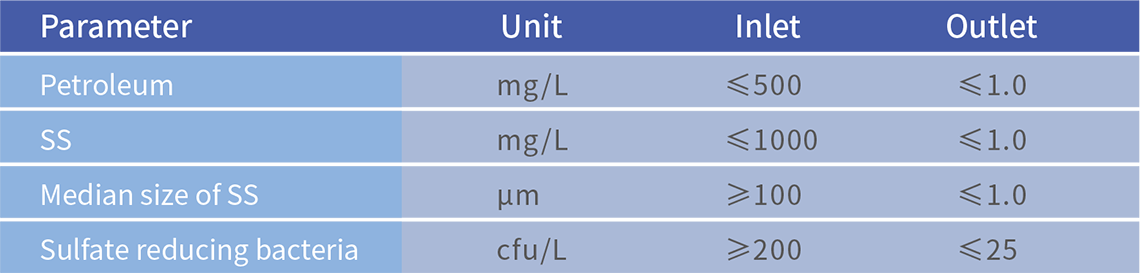

Treatment of oil production effluent is mainly to remove oil and suspended solids to prevent oily water and suspended solids from being reinjected into the oil field which could block the oil production layer. Ceramic tubular membrane technology can be used to achieve oil-water separation.

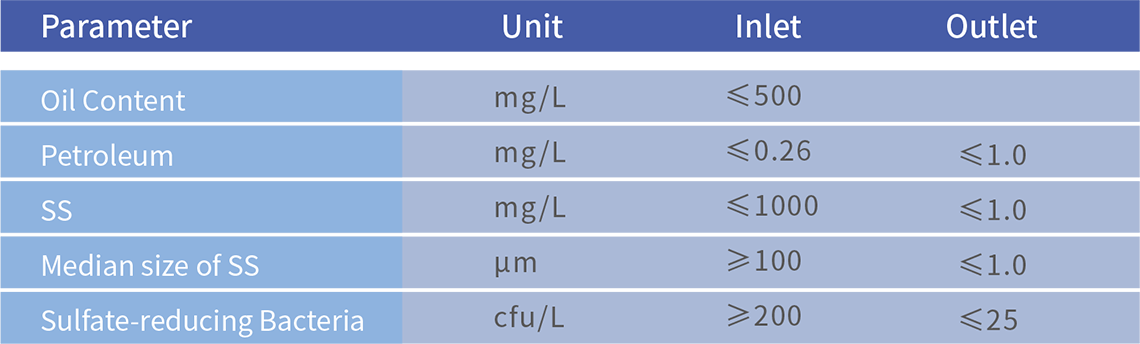

The water quality of oilfield wastewater is complex and contains petroleum, demulsifier, salt, phenol, sulfur, and other pollutants to the environment. The oily sewage of the Yanchang Oilfield Project adopts pretreatment and inorganic ceramic membranes to meet the discharge standards.

The second stage of surface water is pretreated, treated with ultrafiltration and then reinjected. This project includes 1000 m3/d of oily wastewater produced and 1100 m3/d of Hulu River surface water. The treatment capacity is 2100 m3/d.

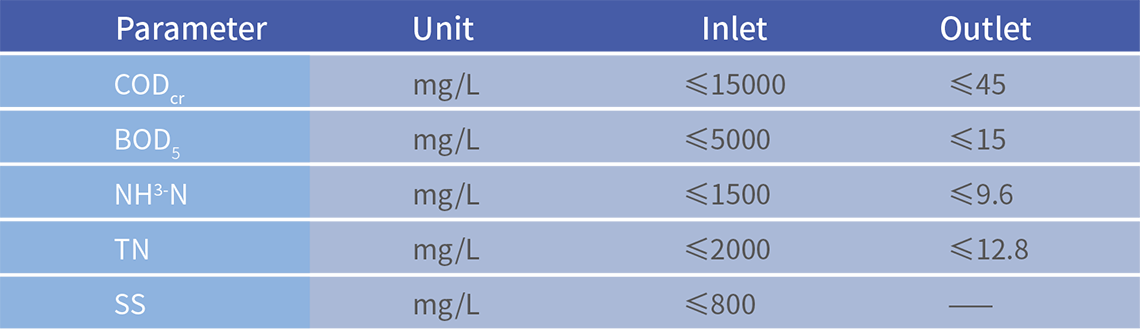

The treatment system needs to be able to handle feed with high concentration and good biodegradability in the beginning and subsequently

feed with low concentration and poor biodegradability, to ensure stable outlet water quality throughout its operation.

Pretreatment + AO + MBR/Ultrafiltration + Nanofiltration/Reverse osmosis

Past project capacity: 3m3/d ‒ 400m3/d

You can ask any questions you may have about our products, our company or our sales processes.

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.