Get a Quote

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.

Welded plate heat exchangers could be good alternative in these kind of cases;

When the gasket resitance is not enough you will have to consider two option in order to go to welded plate heat exchangers;

Then, the thermal duty has to be considered for all king of welded units;

Another parameter is about the fouling fluid requirement and these requires below ;

Then we have these welded plate heat exchangers option for your needs at best technical option wit our experience

S&T Heat exchangers will stay together with humanity because of enormous application requirement even though high cost and many other disadvantageous.

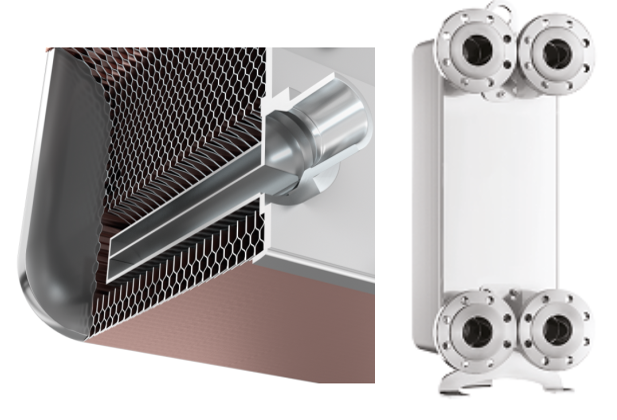

Please keep on your mind that welded plate heat exchangers have high degree of heat transfer, up to five times greater than a shell-and-tube. When you have right criteria then you will be very satisfied with your welded plate heat exchangers. Welded Plate heat exchangers has been applying in the industry since last 40 years with very successful results like interchangers, condensers, reboilers, coolers and heaters application.

SHELL&PLATE Example

Fully Welded Plate hex Example

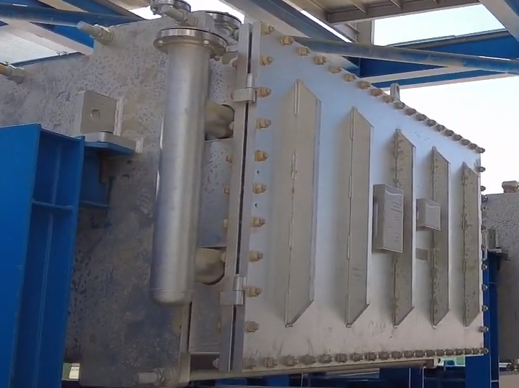

Massive AISI316L Fully Welded PHE

You can ask any questions you may have about our products, our company or our sales processes.

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.