Get a Quote

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.

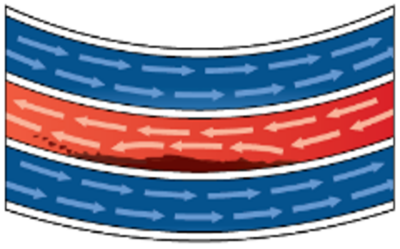

Our spiral heat exchangers can be used without any clogging

problem even in processes with a risk of clogging in very heavy

conditions.

Channel velocities very important for different working condition and

cases at the same heat exchanger position

The most important feature;

As tailor-made, it can be designed for any need like Liquid\Liquid Heating, Preheating, Cooling, Interchanging,

Vapor\Liquid -Top Condenser, Reflux Condenser, Vacuum Condenser, Vent Condenser, Re-boiler which and when require to handle Fouling Liquids containing high amount suspended solids and fibers, Highly Viscous

Fluids like thick Liquors, slurries and sludge and also vacuum application.

• PED, ASME VIII Div-1 , U Stamp or Kinam Std PV codes applicable

• DIN or ANSI Flanges up to PN16

• Channel spacing between 5 mm to 25 mm (as a single channel).

• it can be designed with easy openable hinge covers if requested to be cleaned (as shown )

• “No gasket” gives us to use it against the gasket corrosive fluids application(only cover gaskets)

• It can be designed horizontal or vertically according to the process. (Single or two phase application)

• Maximum 300 °C design temperature and 13 barg design pressure available

• Maximum differential pressure up to 10 barg

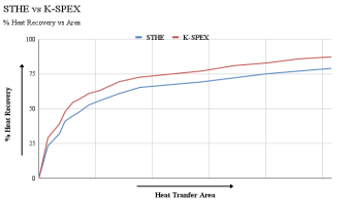

• We completed a design for a spiral heat exchanger based on our experts with software checks HTRI,ChemCAD and ProHE with best optimisation

• Type-2 condenser are also available for many different application

You can ask any questions you may have about our products, our company or our sales processes.

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.