Get a Quote

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.

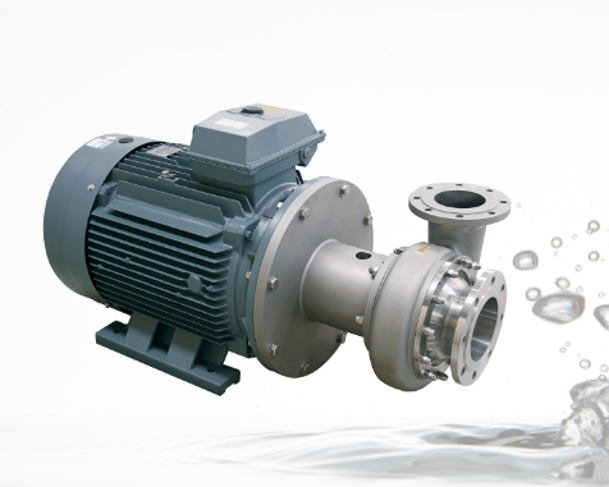

YKH series pump is a forging-high standard sanitary and clean centrifugal pump developed by Shanghai Yuanan on the basis of 20 years of centrifugal pump production and technical summary, specially for customer technical innovation. The characteristic is that the stainless steel round steel for the pump body and the pump cover is solid-soluble and aging after being forged by a friction press, and is processed and formed by ABB manipulator and CNC machining center at one time. After forging processing, the surface is smooth, no fine pores, high hardness, good strength, high material compactness, and better corrosion resistance and cavitation resistance during long-term use. The pump body bears high pressure. The pump shaft of our company uses special stainless steel, which has high strength, hardness and strong corrosion resistance. The two materials are not easy to bite in high-speed operation, and are easy to disassemble during subsequent maintenance. The impeller adopts open design, by CNC processing molding, the high-precision dynamic balancing machine detection, to ensure that the pump is running more smoothly, low noise. The machine seal adopts external balance type, which is cleaner and more stable in use. The whole processing process adopts smooth transition, no dead angle, fully meets the requirements of aseptic hygiene, conforms to online CIP and SIP, conforms to the American 3A cleaning standard certification and European sanitary equipment EHEDG certification. Shanghai Yuanan YKH series forging-high standard sanitary clean centrifugal pump has become one of the first choice for global customers to transport fluids.

YPE series pumps are specially designed and developed by our company for customers, especially suitable for evaporators. The pump cover is made of stainless steel thickened forgings, with high strength, good rigidity, smooth surface and no fine pores. The pump cavity flow channel is optimized according to the principle of fluid dynamics to ensure that the material is transported smoothly, softly and smoothly, to minimize the heating effect on the material, to ensure that the pump is efficient and stable, and has good cavitation resistance. The pump shaft of our company adopts special stainless steel, which has high hardness, good strength and good corrosion resistance. The mechanical seal adopts classic built-in design, which is stable and reliable. The impeller adopts open design, which fully meets online CIP and SIP. Shanghai Yuanan YPE series sanitary pump has become the best choice under high vacuum and negative pressure conditions.

•The pump body adopts spiral design, which is especially suitable for material conveying of concentration equipment.

•Pump body material: SUS304, SUS316L

•Usage flow rate: 1 m³/h-80m/h

•Outlet pressure: up to 12bar

•Motor power: 0.75 kw-37kw

•Speed: 2900r/min.

YAHH series material-liquid mixing pump is designed and developed by our company for customers, which can quickly realize the uniform mixing of powder and liquid. YAHH pump is composed of hopper butterfly valve, upper pump body, lower pump body, impeller, pump shaft, mechanical seal, connecting bracket, base and motor. When the pump is running, negative pressure is formed in the liquid re-pump cavity, and the powder is sucked into the pump cavity by the hopper. Under the centrifugal force and stirring effect of the impeller, the powder and the liquid are quickly dissolved with the liquid. Under the centrifugal force of the impeller, the dissolved liquid is discharged from the pump outlet. YAHH pump structure is simple, easy to use and maintenance, can meet the online CIP and SIP.

YKH D series standard pump is specially designed and developed by our company for customers. It is to add an eccentric guide wheel on the basis of YKH series pump. When the pump is running, the liquid forms a liquid ring in the eccentric guide wheel cavity under the action of the eccentric guide wheel, thus realizing gas-liquid mixed transportation. On the basis of YKH pump body, an eccentric guide wheel cavity is added to the pump body. The impeller adopts open design and is formed by CNC at one time. After being detected by high-precision dynamic balancing machine, the pump runs more smoothly and has low noise. The machine seal adopts external balance type, which is cleaner in use. The whole processing process adopts smooth transition and no dead angle, which is especially suitable for the equipment essential for liquid transportation and return in online CIP and SIP systems.

YPJ series pumps are specially designed and developed by our company for customers for nearly 20 years. The characteristic is that the pump body is welded and formed with stainless steel plate thickness, with smooth surface, no fine pores and no casting defects. The pump cavity flow channel is optimized according to the principle of fluid dynamics to ensure smooth, soft and smooth material delivery, minimize the heating effect on the material, and ensure the efficient and stable work of the pump. The pump shaft of our company adopts special stainless steel, which has high hardness, good strength and good corrosion resistance. The connection between the pump and the motor adopts the design of the lengthened intermediate connection section. When the mechanical seal is replaced for subsequent maintenance, there is no need to disassemble the inlet and outlet pipes of the pump or move the motor. The mechanical seal can be replaced only by removing the intermediate connection section. After replacing the mechanical seal, because the pump body and motor have not moved, there is no need to readjust the concentricity of the pump to ensure that the pump is in the same operating condition as the pump just leaving the factory after maintenance. Mechanical seal with external design, stable and reliable, more clean, fully meet the online CIP and SIP. Shanghai Yuanan YPJ series pumps have become one of the first choices for global users in the field of large flow sanitation.

YAK series pump is a high standard sanitary and clean centrifugal pump with "YKH forging-high standard sanitary and clean centrifugal pump" developed by Shanghai Yuanan on the basis of 20 years of centrifugal pump production and technical summary and specially developed for customer technological innovation. The advantage is that the pump body is made of 2B stainless steel thick plate through high-precision mold forming. The stainless steel round steel for the pump cover is solid-soluble and aging after the overall forging of the friction press, and is processed and formed by the CNC machining center at one time. The surface is smooth and has better corrosion resistance and cavitation resistance during long-term use. The pump shaft of our company uses special stainless steel, which has high strength, hardness and strong corrosion resistance. The two materials are not easy to bite in high-speed operation, and are easy to disassemble during subsequent maintenance. The impeller adopts open design, by CNC processing molding, the high-precision dynamic balancing machine detection, to ensure that the pump is running more smoothly, low noise. The machine seal adopts external balance type, which is cleaner in use. The whole process adopts smooth transition, no dead angle, fully in line with online CIP and SIP. Shanghai Yuanan YAK series pumps have become one of the first choices for fluid transportation for a wide range of customers at home and abroad.

YPE series pumps are specially designed and developed by our company for customers, especially suitable for ultrafiltration system. The characteristic is that the pump cover is made of stainless steel thickened forgings, with high strength, good rigidity, smooth surface and no fine pores. The pump cavity flow channel is optimized according to the principle of fluid dynamics to ensure that the material is transported smoothly, softly and smoothly, to minimize the heating effect on the material, to ensure that the pump is efficient and stable, and has good cavitation resistance. The pump shaft of our company adopts special stainless steel, which has high hardness, good strength and good corrosion resistance. The mechanical seal adopts classic built-in design, which is stable and reliable. The impeller adopts open design, which fully meets online CIP and SIP. Shanghai Yuanan YPE series sanitary pump has become the best choice under high vacuum and negative pressure conditions.

YAG series pump is our company specially designed for customers easy to disassemble sanitary centrifugal pump, which is characterized by the pump head and pump cover, import and export are quick connection, simple structure, easy disassembly. The outlet of the pump head is divided into left outlet and right outlet. The impeller adopts full-start impeller, which is divided into forward and reverse impellers. The pump shaft is made of special stainless steel with high strength and good hardness. This series of pumps fully meets the online CIP and SIP.

You can ask any questions you may have about our products, our company or our sales processes.

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.