Get a Quote

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.

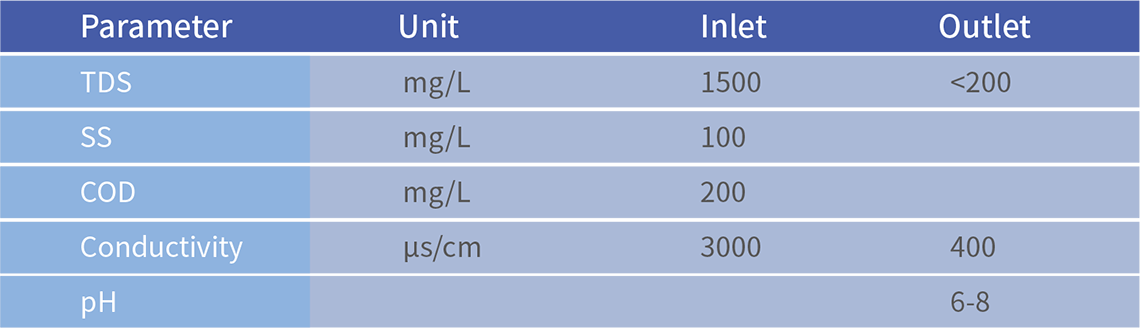

The water recycle project of Tongliao Meihua Bio-Tech Co. Ltd is located in Tongliao city, Inner Mongolia. It uses double membrane process to

remove the impurities in anaerobic and aerobic treated wastewater to reuse in desalinated water system for the power plant. This project includes reclaimed water from both west and east sector with flow rate of 10000m3/d and 12000m3/d respectively.

Pretreatment + Ultrafiltration + Reverse osmosis

Past project capacity: 330m3/d ‒ 22000m3/d

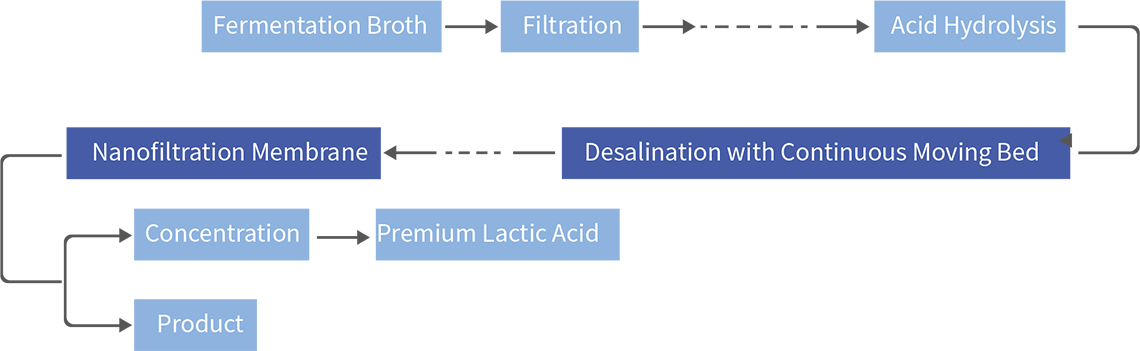

Suntar, together with organic acid production companies, developed a series of membrane technologies combined with continuous moving bed technology for the production of organic acids based on years of membrane application and engineering experience.

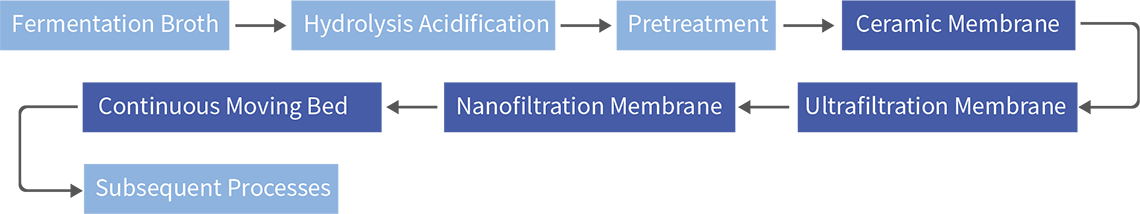

Nanofiltration: Reduce reducing sugar concentration in the product which increase its thermal stability. Membrane filtrations produce high quality lactic acid.

Continuous moving bed ion-exchange process greatly increases resin utilization and reduce material consumption.

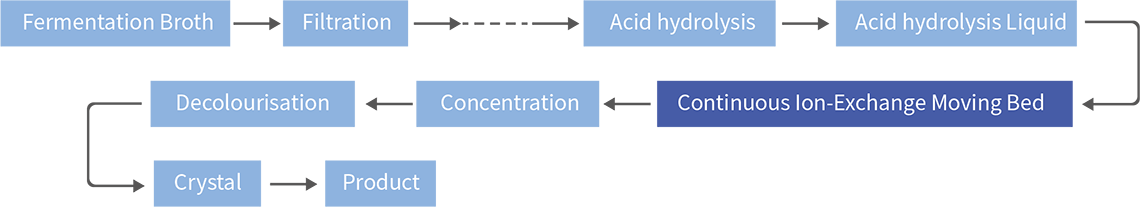

The traditional citric acid extraction method calcium salt precipitation method which is hindered by the low filtration quality of traditional filtration processes which causes problems to the subsequent processes.

Suntar developed continuous ion-exchange technology for clean production of citric acid based on many years of membrane application and engineering experiences which revolutionized the citric acid production industry.

Continuous ion-exchange with increased resin utility reduces material consumption and increases citric acid product concentration

Vitamin is an organic molecule that is an essential micronutrient that an organism needs in small quantities for the proper functioning of its metabolism.

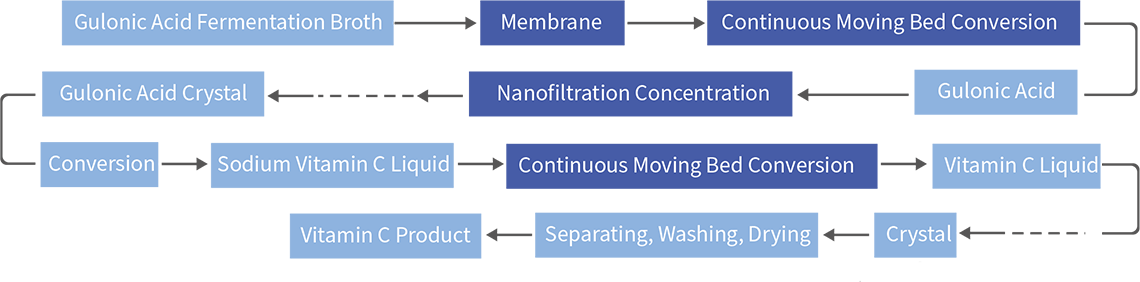

Initially, Suntar worked together with many vitamin companies to apply both membrane separation technology and continuous moving bed technology into vitamin production which achieved significant results in multiple vitamins including, Vitamin C, Vitamin B2, Vitamin B12, etc. Suntar revolutionized the extraction process of Vitamin C by successfully developing a Vitamin C production process based on membrane separation and moving bed technology. This greatly reduced the production cost and turned China's Vitamin C from the yellow“ Cuban sugar” to“ white sugar” grade.

Suntar designs the safest and most suitable complete process for the production and extraction of vitamin C with internationally leading technology.

Membrane filtration of vitamin C fermentation broth with accurate MWCO achieving high quality filtrate and recovery > 98%.

Concentration of gulonic acid to over 16% with nanofiltration reduces steam consumption and greatly reduces operation costs.

Continuous ion-exchange moving bed system reduces the resin consumption by 70% for both sodium gulonate and sodium vitamin C conversion process. Greatly reduce water, acid and alkaline consumption to achieve clean production.

Ceramic membrane removes impurities in fermentation broth, achieving high filtrate quality.

Ultrafiltration membrane further removes smaller proteins, improving subsequent resin performance.

Concentrate Vitamin B12 with membrane, improving subsequent resin adsorption rate.

Continuous ion-exchange reduces resin consumption, significantly reduces water and chemical consumption achieving clean production.

You can ask any questions you may have about our products, our company or our sales processes.

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.