CONDENSER

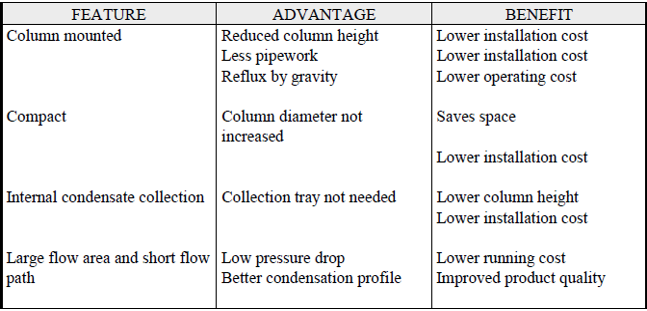

the most common application mainly in refining application and lets have a look general information about the universal and classic distillation units Then, our solution can be review with advantegous on the right

The distillation unit

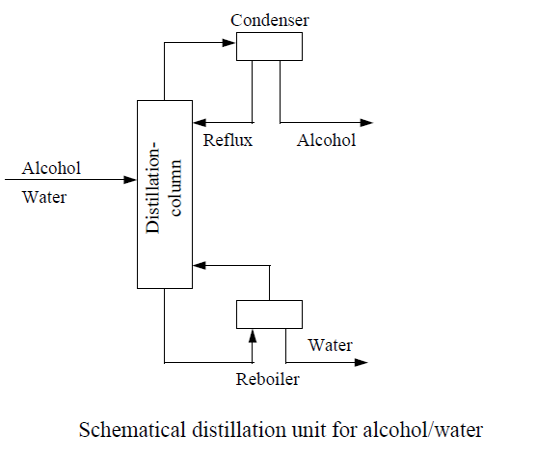

In order to accomplish the separation we need to have as good contact as possible between the two phases. This contact is achieved in the distillation column. Distillation is probably the unit operation that has the most varied equipment, but the following parts are usually found in a column:

• cylindrical tower

• plates, trays or packing

• reboiler

• condenser

The column

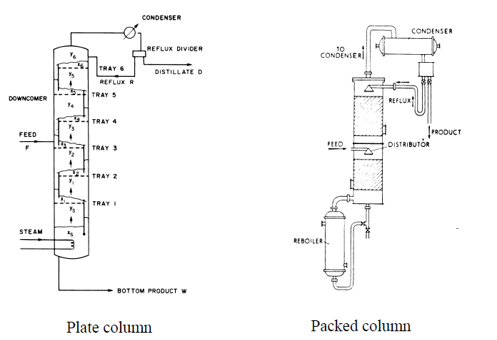

Normally a distillation column belongs to one of the two following major types depending on its internal arrangement:

• plate columns - the column is provided with a number of separate trays

• packed columns - the column is filled with a packing

In plate columns, which is the most important type, the contact between liquid and vapor is achieved in a stagewise manner on each tray whereas with packed columns the contact be-tween the liquid and the vapor is continuous.

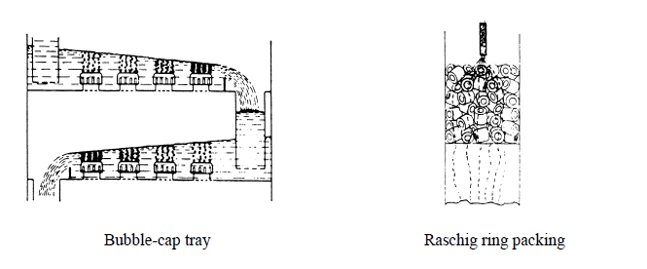

For plate columns the most common types of plates (trays) are:

• bubble-cap trays

• sieve trays (perforated trays)

• valve trays

Packed columns are normally filled with some type of rings that provide the necessary contact between the two phases. The most common types of packings are:

• Raschig rings

• Pall rings

• Lessing rings

• Berl saddles

Please find the Video explaining the Inside of the Corrugated Tube Heat Exchanger explains the benefits of CTHE, you can also see the difference between the Laminar and the Turbulent flows inside the plain and corrugated tubes respectively;

The theory is good, but sometimes it still becomes difficult for the customer to trust and believe that it's true, so we at Kinam took this as a challenge and designed as well as manufactured a Test-Rig to show the live comparison between a conventional Shell & Tube Heat Exchanger and a Corrugated Tube Heat Exchanger providing the same Heat Load to both. You will be able to see the difference in live condensation in both the heat exchangers, in Corrugated Tube Heat Exchangers - Dropwise condensation which is more efficient whereas in Plain Tube Heat Exchangers we have Filmwise condensation;

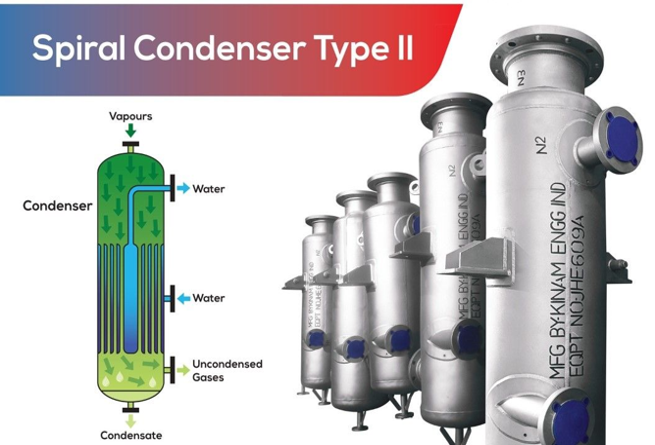

Condenser

A condenser condenses the vapor leaving the highest tray.

The amount of liquid that is neces-sary for the contact between vapor and

liquid is provided as a reflux of the condensed vapor to the highest tray.

The rest is withdrawn as the distillate. There are two possible ways to condense the vapor from the highest tray.

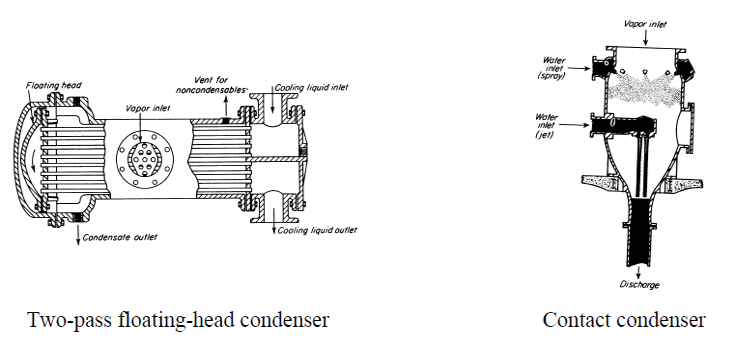

• total condenser - where all the vapor is condensed and a part of the liquid is refluxed

• partial condenser - where only a part of the vapor is condensed and withdrawn

Two typical condensers are shown on the right side

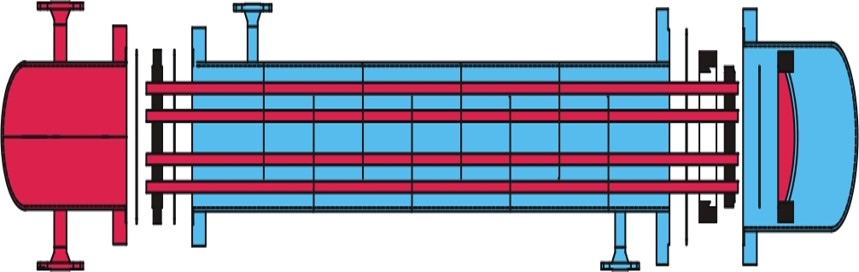

919m2 Propylene Feed Column Condenser,

1280 no’s of U-Tubes, Weight : 46 Tonnes

Cumene Plant,

1458m2 Depropanizer Condenser

Floating head bundle of 4032 Nos. tubes,

Weight : 55 Tonnes

Phenol Plant, Gujarat, India

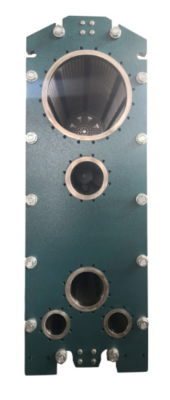

This special condenser plate pack with semi-welded channels and traditional gasketed on the cold side channels. All cold side plate surfaces are easily accessible for inspection and manual cleaning in case of fouling presence. This cleaning job can be completed in a very short time period.

The frame has two heavy frame plate of painted carbon steel between which the plate pack is kept together

by means of tightening bolts like a standard plate heat exchanger.

It is special for vacuum condensation. The large vapour inlet connection is placed centrally on the top and

the smaller condensate outlet on each side at the bottom. The two medium sized connections for cooling media

or heated media are centrally placed in the middle.

The semi-welded cassette concept with the plates welded in pairs. The vapour is condensed in the welded channel while the cooling water passes through a gasketed channel. The plate pattern is specifically designed for optimal condensation, with an asymmetric channel configuration that features a large gap on the vapour side and a small gap on the cooling water side. This makes it possible to maintain a very low pressure drop on the vapour side while still keeping up the velocity and turbulence on the cooling water side, thus maximizing the heat transfer efficiency and minimizing fouling.

Condensing capacity up to 75,000 kg/hr of vapour depending on process operating conditions with DN800 connection for low pressure vapours.

- Operating pressures down to 0,05 bar available.