EVAPORATION

Evaporation is the main method used to increase the concentration of a solution. The solvent, normally water, is removed by heating a diluted solution and withdraw the vapor. When the solvent is seperated, the concentration of the dissolved matter increases. Evaporation is a common unit operation in a variety of industries:

Industries

• Sugar

• Distillery

• Pulp & Paper

• Alkali

• Alumina

• Soda Ash

• Food

• Other inorganic

• Pharmaceutical

The evaporator mainly consists of a heat exchanger and a separator that are built together. The energy is usually supplied by letting steam condense on one side of the heat transfer surface. The heat of condensation is transported to the solution on the other side. The solvent boils off and the vapor that is formed is separated from the concentrated solution in the separator.

There is a wide range of different types of evaporators used in industry today. There are also possibilities to connect several units in series. In these multiple effect installations there are also possibilities to use cocurrent flow, countercurrent flow or a mix. the plate evaporator as an attractive alternative in many applications, but also normal PHE’s can be used for evaporation duties.

• sugar juice

• stillage

• black liquor, sulphite liquor,

• effluent water

• NaOH

• CaCl2

• milk,

• fruit juice,

• beer,

• coffee& tea

• Food gelatin

• waste water,

• weak acids,

• phosphoric acid,

• urea, NH4NO3,

• NaCl and many other inorganic salts

• vitamins,

• enzymes,

• insulin,

• antibiotics

Industries

• Sugar

• Distillery

• Pulp & Paper

• Alkali

• Alumina

• Soda Ash

• Food

• Other inorganic

• Pharmaceutical

The evaporator mainly consists of a heat exchanger and a separator that are built together. The energy is usually supplied by letting steam condense on one side of the heat transfer surface. The heat of condensation is transported to the solution on the other side. The solvent boils off and the vapor that is formed is separated from the concentrated solution in the separator.

There is a wide range of different types of evaporators used in industry today. There are also possibilities to connect several units in series. In these multiple effect installations there are also possibilities to use cocurrent flow, countercurrent flow or a mix. the plate evaporator as an attractive alternative in many applications, but also normal PHE’s can be used for evaporation duties.

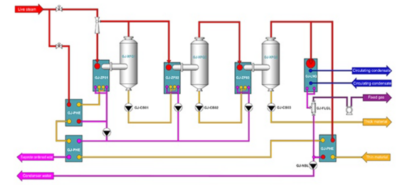

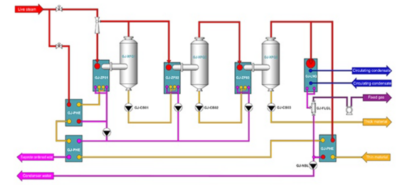

Multieffect MVR – Lactic Acid Evaporator

4Effects – Maltoz concentration

Product process diversification: multi-effect evaporation system, TVR evaporation system, MVR evaporation system, MVR + TVR evaporation system, flash evaporation system, falling film evaporation system, forced circulation evaporation system, evaporation crystallization system, plate and column mixing Nearly ten kinds of processes, such as evaporation system and cross-flow evaporation system, can meet the needs of different processes and different customers at any time.

5 Effect Apple Juice Evaporator – 8tph

Blood peptide MVR single effect evaporator

There are many excellent performances of multi-effect evaporators, such as wide heat transfer area, large flow control panel, good heat transfer performance, easy configuration, and multiple processes, etc., which are important reasons why multi-effect evaporators have become more popular machinery and equipment today.

The multi-effect evaporator is an evaporation operation mode in which several evaporators are connected in series to operate together, so that the steam heat can be used multiple times, thereby improving the utilization rate and efficiency of evaporation and energy heat, and has been mostly used in aqueous solution treatment. industry. In the entire working process of the multi-effect evaporator, the first evaporator uses the new steam as the heating steam, and the other several effects use the secondary evaporation of the previous evaporator as the main heating steam, so that it can be well Reduce the amount of steam used, each of which has its own unique task. The secondary steam temperature in each of these effects is always lower than the previous heating steam, so there are many effects of evaporation so that the operating pressure and page boiling will decrease with the increase of steam heating steps.