ABSORPTION/STRIPPING

If the absorption process is reversed, i.e. the absorbed component is driven off, it is called stripping or desorption. This stripping is accomplished by decreasing the pressure and/or in-creasing temperature, It is very common to use a combination of absorption and stripping in order to separate a product from its byproduct(s).

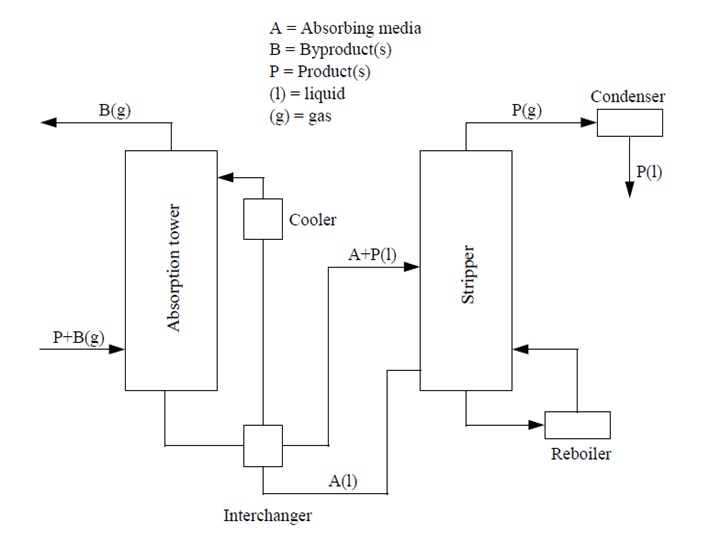

The mixture of products and byproducts is fed to an absorption tower. In the absorption tower the desired product is absorbed in a liquid and the byproducts leaves the tower at the top. The liquid, which is now containing the desired product, is brought to a stripper. In the stripper, the liquid mixture is separated by means of changing the temperature or pressure so that the desired product is taken out as a gas in the top and the absorbing liquor is taken out in the bottom and recycled to the absorption tower.

As mentioned it often necessary to cool the absorbing liquid before it enters the absorption tower. The liquid entering the stripper, on the other hand, needs heating. These two facts makes it ideal to interchange the two streams like in the picture above. This is normally a very good position for a PHE/WPHE or SHE or Tubular. The cooler before the absorption tower is also a very good position for our products.