REBOILERS

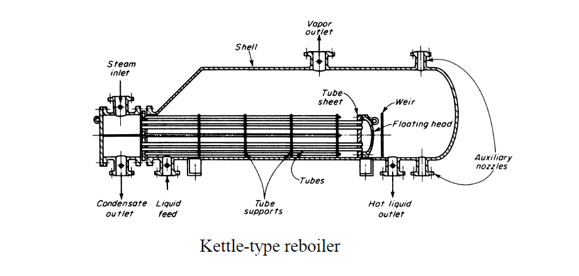

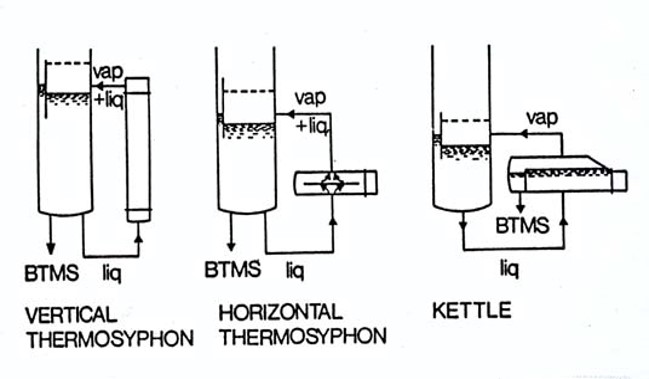

The liquid that leaves the lowest tray in the distillation unit is brought to a reboiler. The re-boiler generates the vapor that needs to be provided to the lowest tray. The amount of liquid that is not vaporised is withdrawn as the bottom product. A typical reboiler is shown below.

An efficient way to accomplish this multiple vaporisation/condensation is to use an apparatus, called the distillation column. The distillation column normally consists of a number of so called trays where vaporisation/condensation can occur. On the top of the column, there is a condenser that condenses the distillate and in the bottom of the column there is a reboiler, which provides the heat that is necessary. Part of the distillate is brought back to the column, this is called reflux.

Reboiler can also be designed with plate bloc type heat exchangers

Especially in case of exotic material needed

High temperature

High pressure

Easy cleaning required

Not deal with tradational gasket and high resistant gaskets on the panels only

Very compact and low cost conparing to S&T