Get a Quote

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.

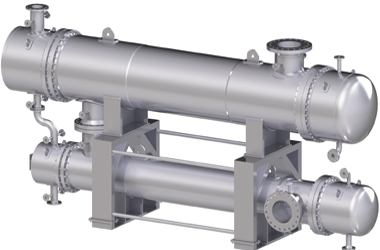

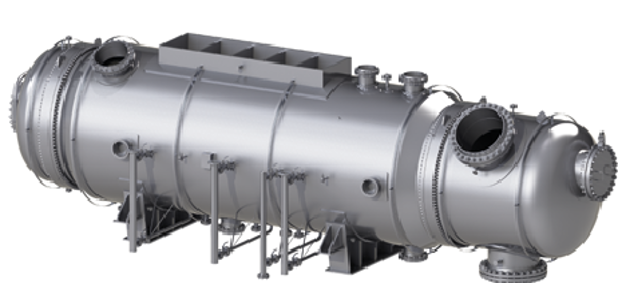

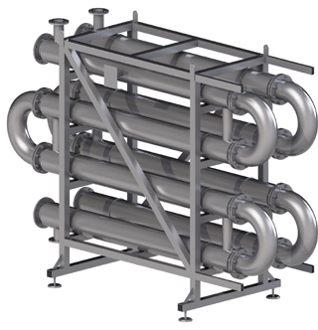

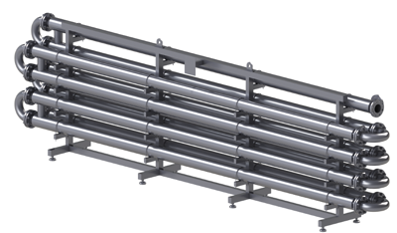

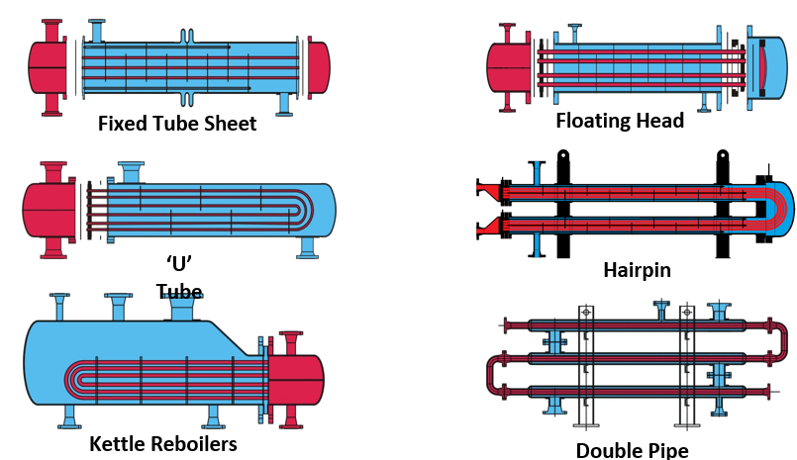

We as Alfa Process , able to design for your needs for the best performing heat exchanger selection by considering your technical creiterias for your needs based on your duty requirements like very high pressure and temperature limits which can not be handled with other alternative in a feasible way.

In case of requirement we can also provide refurbisment of your plate heat exchanger and servicing in required planning periods wihout creating any hold up time in your process.

You can contact with us for your inquiry , info@alfaprocess.com.tr

please email to us or fill the form at the link below

https://alfaprocess.com.tr/request for a quotation

Height under crane hook - 12 meters

Material Handling Capacity ~350 MT/month (single equipment of 100 MT capacity)

Pharma-Grade Clean room Facility of 1000 sq. ft. dedicated to superior welding quality for Exotic Materials

In-house Painting Room and Shot Blasting Room for better quality control and improved equipment quality.

In-house CNC Drilling, CNC Plasma Cutting, Laser Cutting, Shell Rolling machines with pre-pinching facility, 7 radial drill machines with 24 hours drilling, Orbital Welding Capabilities

Manufacturing capacity from 1m2 to 4000m2 HTA

Capacity to execute jobs upto 8 meters dia and max length upto 25 meters length.

General design Parameters

Materials : Carbon Steel, AISI 304L / 316L/ Titanium / Alloys exotics

Design Pressure : up to PN200

Design temperature : -190°C to + 750°C

The Max Length : 25 meter

Shell diameter max : 4000 mm

Heat transfer area max : 4000 m²

Tubes : 10 mm to 350 mm

Gaskets only covers : Tephlon and CNAF or alternative

We are able to maufacture your specific needs , please contact for further information

info@alfaprocess.com.tr

You can ask any questions you may have about our products, our company or our sales processes.

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.