Get a Quote

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.

We as Alfa Process , able to design for your needs for the best performing heat exchanger selection by considering your technical creiterias for your needs based on your hygenic requirement and thermal duty requirements together.

In case of requirement we can also provide refurbisment of your plate heat exchanger and servicing in required planning periods wihout creating any hold up time in your process.

You can contact with us for your inquiry , info@alfaprocess.com.tr

please email to us or fill the form at the link below

https://alfaprocess.com.tr/request for a quotation

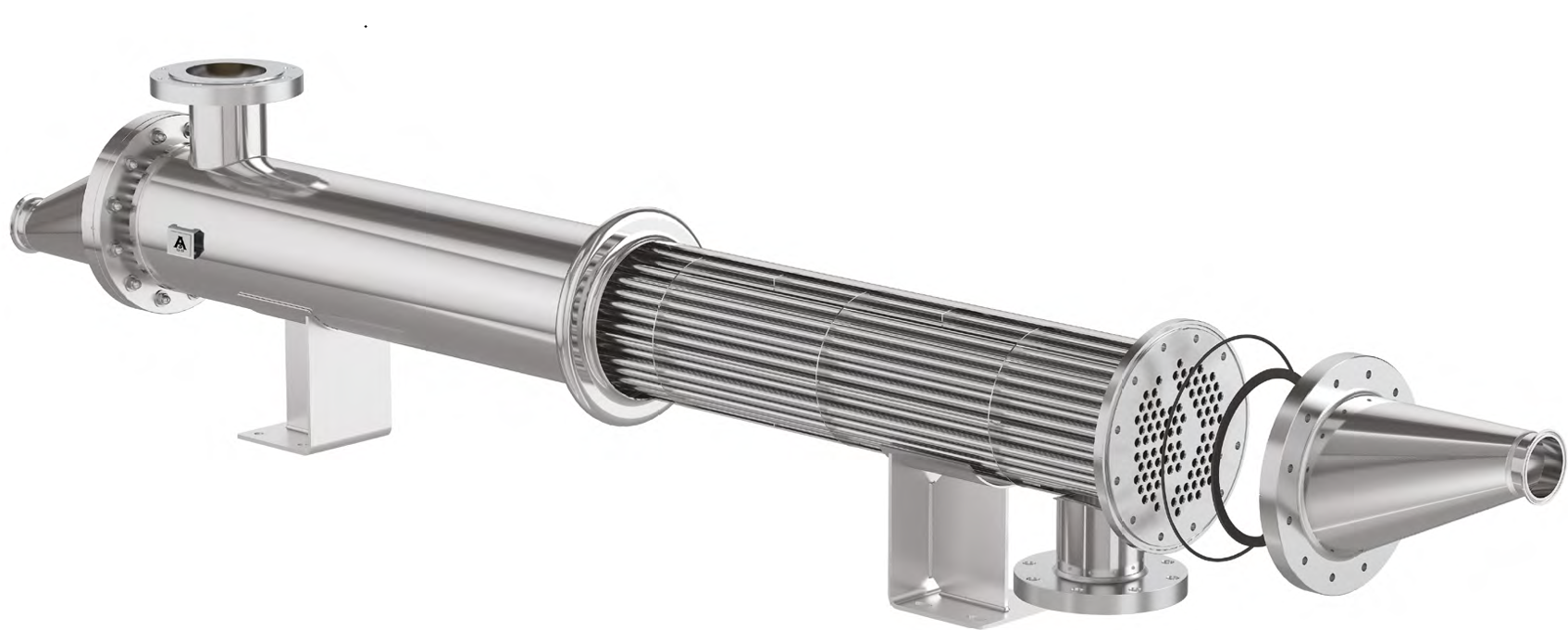

As tailor-made, it can be designed for any need like Liquid\Liquid Heating, Preheating, Cooling, Interchanging,

Vapor\Liquid -and when require to handle different application in the industry and food industry which are the fluids like corrosive, viscous foods, dairy fluids, juices, beer, wine and many other then we have solutions

WORKING PARAMETERS

TUBES

MAX. TEMPERATURE

VITON — 140 ° C ⁄ 284°F

SILICON — 121° C * ⁄ 2 4 9 ° F

MIN. TEMPERATURE

VITON — -17 ° C * ⁄ 1.4°F

SILICON — -25° C ⁄ -1 3° F

MAX. PRESSURE

VITON — 10 BAR ⁄ 145 PSI

SILICON — 10 BAR ⁄ 145 PSI

SHELL

MAX. TEMPERATURE — 200 ° C / 392°F

MIN. TEMPERATURE — -25° C / -13°F

MAX. PRESSURE — 10 BAR / 145 PSI

DNA

· max. temp.: 392°F / 200°C

· min. temp.: -4°F / -20°C

· max. pressure shell side: 145 psi / 10 bar

· max. pressure tube side: 232 psi / 16 bar

You can ask any questions you may have about our products, our company or our sales processes.

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.