Get a Quote

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.

Amino acid is a common name for a class of organic compounds containing amino groups and antelope groups, and there are more than 300 kinds of natural amino acids, of which about 22 kinds of amino acids are needed by the human body. Suntar's integrated separation solutions have been successfully applied in a variety of amino acid production processes, such as lysine, tryptophan, threonine, arginine, glutamine, leucine, valine, isoleucine, homoserine, methionine, citrulline, etc.

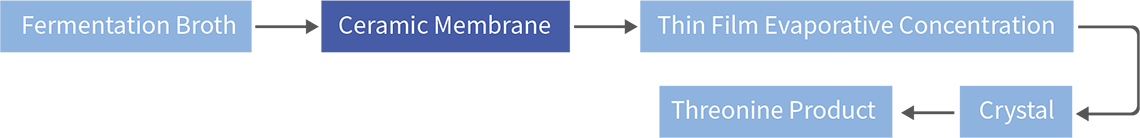

Threonine requires higher filtrate quality from ceramic membrane separation than other amino acids. Suntar developed threonine specific ceramic membrane with high precision and high resistance to abrasion.

Membrane filtration produces clear filtrate with 15% increased resin equivalent weight.

Less impurities in the pillar reduces the amount of water needed for resin regeneration which increase the resin lifespan and total yield.

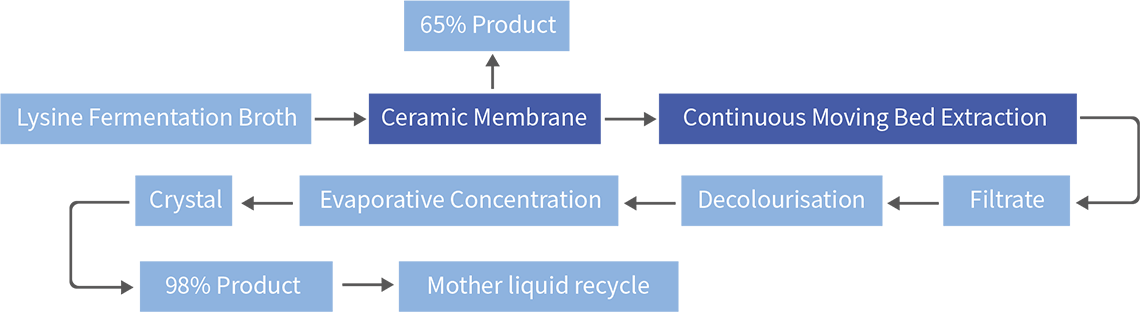

Membrane retains bacteria and protein in the fermentation broth which is then dried and processed into 65% lysine product.

Ion-exchange continuous moving bed dissociative adsorption increases resin utilization rate and the concentration of lysine in the permeate. this also reduces the consumption of water, analytical ammonia and wastewater discharge.

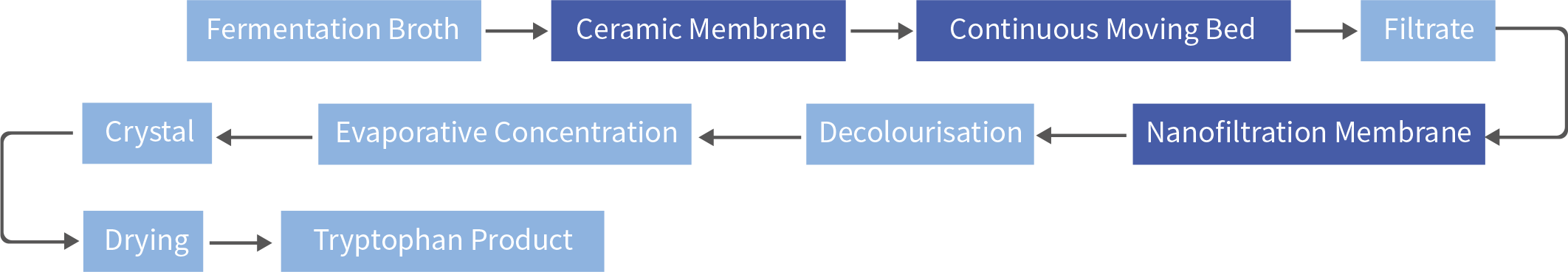

Ceramic membrane removes impurities and clarifies the permeate. This ensures high quality feed supplied to resin that ensures long lifespan of resin.

Continuous ion-exchange reduces chemicals and water consumption.

Nanofiltration removes impurities to improve the light permeability of tryptophan and lower the load of subsequent decoloring process.

With the advancement of technology, Suntar membrane separation and continuous moving bed technology have replaced the traditional antibiotic extraction process. This improves the antibiotic quality and the production environment. These technologies are widely used in many antibiotic productions such as Penicillin, Cephalosporin, Erythromycin, Colistin sulfate, etc.

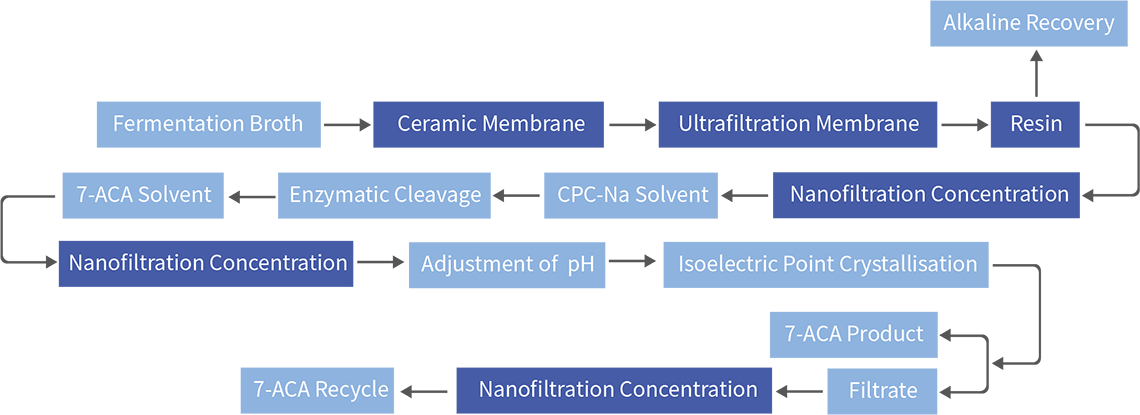

Ceramic membrane filtration clarifies the fermentation broth achieving high filtrate quality.

Antifouling spiral wound ultrafiltration membrane removes potential pollutants from the filtrate to reduce resin consumption in subsequent processes.

Concentrate CPC-Na to over 50000ug/ml with nanofiltration.

Concentrate 7-ACA to over 25000ug/ml with nanofiltration which increases recovery.

Concentrate 7-ACA mother liquor with nanofiltration and recover 7-ACA through recrystallisation.

With the technological advancement, membrane filtration and water phase crystallization are adopted as core technology in production by many companies. This reduces the solvent consumption and achieve clean production of erythromycin.

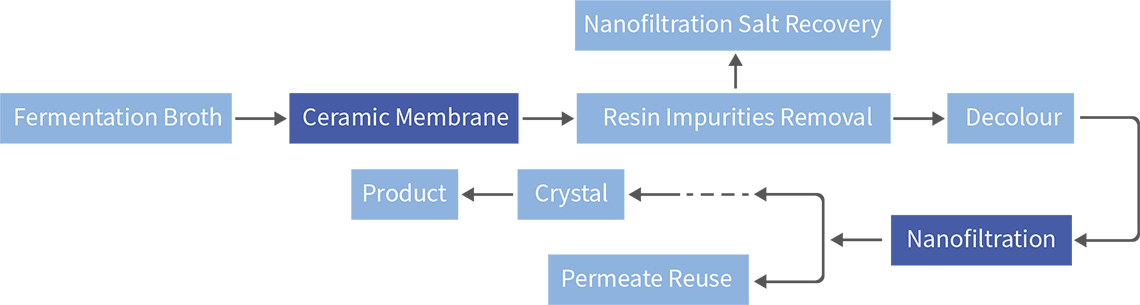

Ceramic membrane filters fermentation broth, removing bacteria and macromolecular substances to obtain clear filtrate. This provides high quality feed for the subsequent resin impurities removal to ensure stable processing.

Nanofiltration concentrates erythromycin up to the level that is suitable for crystallization resulting in filtrate with good quality which can be used in other processes thus reducing wastewater discharge.

Nanofiltration recover waste salt water produced in resin filtration, lower salt consumption.

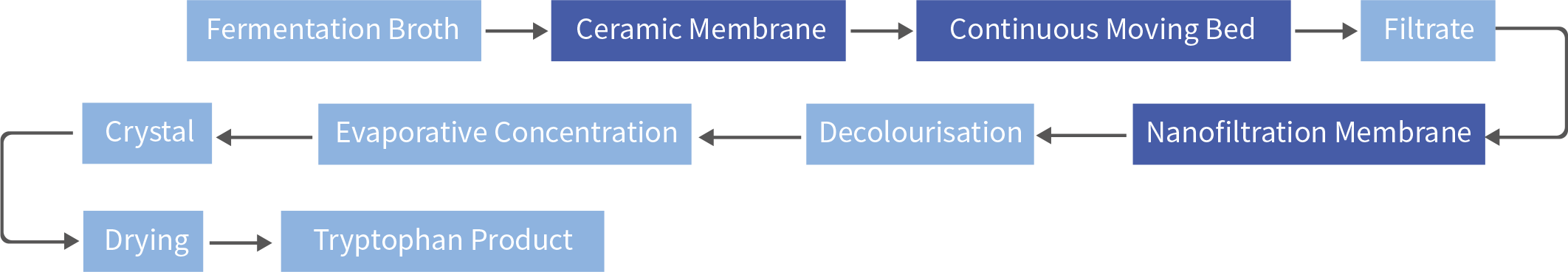

Ceramic membrane removes impurities and clarifies the permeate. This ensures high quality feed supplied to resin that ensures long lifespan of resin.

Continuous ion-exchange reduces chemicals and water consumption.

Nanofiltration removes impurities to improve the light permeability of tryptophan and lower the load of subsequent decoloring process.

In recent years, membrane separation technology in plant extraction has become more abundant. Suntar has also developed many applications in the plant extraction industry and an overall production process based on membrane separation technology and moving bed technology.

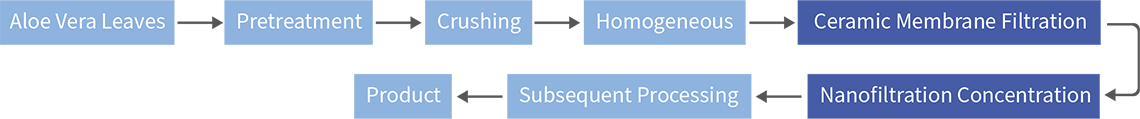

Ceramic membranes remove impurities and clarify extract which improves filtrate quality and recovery.

Nanofiltration concentration increases aloe vera juice soluble solid concentration from 0.75% over 7%

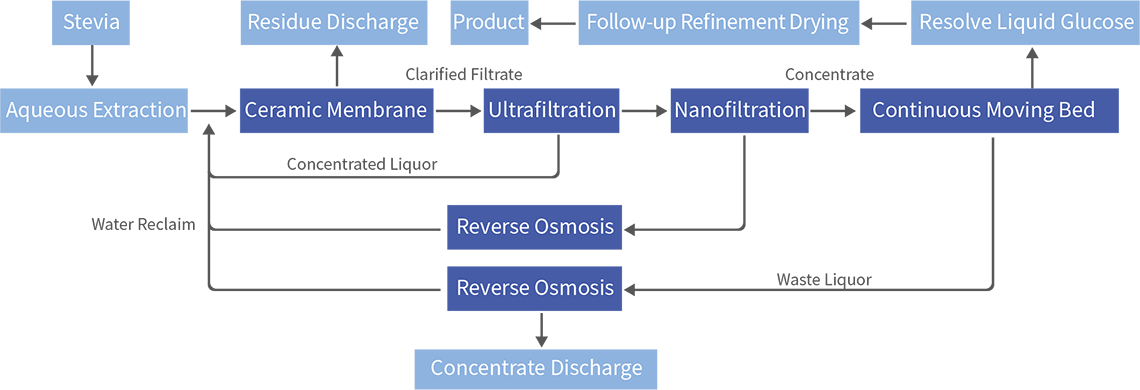

Membrane filtration has ideal impurity removal and clarification effect on stevia extract, and can better remove suspended solids, and pigments as well as improve product quality and yield.

Nanofiltration membrane increases the efficiency of resin adsorption and significantly reduces wastewater discharge. The filtrate can be discharged directly or be treated further and recycled.

Continuous moving bed reduces resin consumption by over 60% as well as reduces regenerant consumption and wastewater discharge by over 50%.

Wastewater treatment in each process becomes simpler with membrane. Membrane filtrate and the lower column waste of the resin adsorption process are fully recovered through reverse osmosis to achieve zero discharge.

Continuous moving bed separates the extract, reduces the resin consumption by 60%, saves more than 50% of the regenerant, and reduces wastewater discharge by more than 60%.

Nanofiltration concentrates the product to meet the needs of the subsequent processes, improves recovery rate and reduces energy consumption.

Wastewater recovery through nanofiltration technology.

Traditional soy sauce production can be simplified by applying membrane separation technology. This eliminate the need of heating in production which retains the colour, fragrance, flavour and nutrients in the condiment. This reduces the pollutant discharge and allows active ingredients to be recycled and reused. At the same time, it can desalinate soy sauce, remove harmful substance and prevent precipitation

Clarify Soy sauce with ceramic membrane to produce clear and transparent soy sauce of high value. After ultrafiltration of light soy sauce, the retention rate of total nitrogen, amino acid nitrogen, salt-free solids, reducing sugar, pigment, etc. are all around 98%.

Desalination of soy sauce by electrodialysis can produce low-salt soy sauce while maintaining the original flavour of soy sauce.

You can ask any questions you may have about our products, our company or our sales processes.

We will contact you within 24 hours via one of the communication channels you have specified.

Your data will be processed under the conditions set out in our Privacy Policy.